|

SUNKYE INTERNATIONAL CO., LTD.

|

Micro Crimp Connectors for Choice

| Place of Origin: | Hong Kong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Sunkye is uniquely qualified to deliver turnkey custom solutions and micro 38999 connectors manufacturer

Sunkye is uniquely qualified to deliver turnkey custom solutions and micro 38999 connectors manufacturer for a complete range of high-performance applications. Our industry-leading materials knowledge, engineering design experience, and testing capabilities are key to achieving reliable service in the most extreme environments. You'll find a large selection of popular Mil-Spec military connectors such as MIL-DTL-83513 micro connector, MIL-DTL-38999 iii connector, MIL-DTL-32139 nano connector, MIL-DTL-26482 automotive connector, d sub connector, micro-d connectors, and more, available in standard or custom configurations of mil connector.

Description of Micro Crimp Connectors

An electrical crimp is a type of solder less electrical connection. Mini crimp connectors are typically used to terminate stranded wire. Crimping is normally performed by first inserting the terminal into the crimp tool. The terminal must be placed into the appropriately sized crimp barrel. Crimp-on connectors are attached by inserting the stripped end of a stranded wire into a portion of the connector, which is then mechanically deformed/compressed (crimped) tightly around the wire. Sunkye Micro crimp style connectors matching with standards MIl-DTL-83513 and accept standard jackscrews and jackpots, making it ideal for flex-to-board applications, which widely used in the military area, aerospace, aviation, electrical, ship-building, defense system, etc.

Performance of Micro Crimp Connectors

Contact Pitch * 0.050˝ (1.27 mm)

TEMPERATURE RANGES *

- STANDARD -55°C / +150°C

- HIGH TEMP -55°C / +200°C

Vibration * 10Hz-2000Hz, 196m/s2

Contact arrangements of Micro Crimp Connectors

Metal shell: 9, 15, 21,25,31,37,51,66,74, 100 contacts

Plastic shell: 9, 15, 21,25,31,37, 51 contacts

Introduction of Micro Crimp Connectors

Series * Micro D Connector

Terminal Mounting * Crimping Cable Assembly

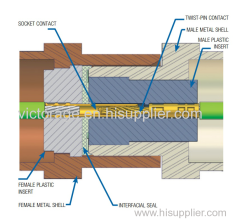

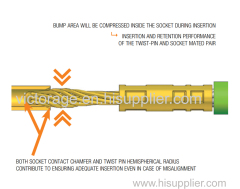

Contacts *Twist pin contacts, high density interconnection, Becu, gold over nickel plating

Thickness of Gold plating * ≥1.27micron

TWIST PIN * Male contact, fitted to plug connector.

Socket * Female contact, fitted to socket connector (also known as socket).

Insulator* 20% GFPPS (20% glass filled polyphenylene sulfide)

Insert * Moulded insulation housing, separating each connection.

Interfacial Seal * Fitted to socket connector only

Shell *Connector metal body plated nickel or cadmium.

Jackscrew *High or low profile, hexagonal socket or slotted head.

Jackpot* Mates with jackscrew.

Cable * AFR250 (PTFE) MIL-DTL-681

Wire length * ≤6 meters (Recommend)

Standard crimp style connectors * Manufactured to the standard dimensions and specifications.

Special crimp style connectors * A standard connector modified to meet specific requirements.

Custom-made crimp style connectors * Designed to meet specific customer requirements.

Pigtail crimp style connectors * Connector with insulated or uninsulated wires.

Harness * Multi-branched cable assembly.

LCP * Liquid Crystal Polymer.

Potting * Epoxy compound used as an encapsulant.

Frequently asked questions about Micro Crimp Connector

Are crimp style connectors good?

A good micro crimp connector can be used on solid or stranded conductors, and provides a good mechanical and electrical connection

Is it better to solder or crimp?

Crimping offers stronger, more reliable connections than soldering. Soldering uses heated metal to join the cable to the connector. Over time, this filler metal will degrade, which may cause the connection to fail. Most electricians will agree thatcrimping is also easier than soldering.

What is micro crimp style connectors used for?

Crimp connections are used typically to fix connectors, such as BNC connectors, to coaxial cables quickly, as an alternative to soldered connections. Typically the maleconnector is crimp-fitted to a cable, and the female attached, often using soldered connections, to a panel on equipment.

Related Search

Find more related products in following catalogs on Hisupplier.com

Related Products

-

6mm Signal pins with Silver plating 3um for Solar charging wall receiverEU-02-002 6mm silver plating pins

.jpg)

.jpg)

.jpg)

.jpg)